通过我们在您装配线上的智能制造指导提高生产效率并保持优势

了解数据驱动工艺、全面可追溯性、高效工具管理、轻型自动化等策略。探索马头动力工具的专业解决方案。

提高生产力和更智慧地工作是保持竞争优势的关键。引入智能制造流程,随着时间的推移随着业务的发展而发展,可以提供您需要的灵活性,以重新平衡生产流程以响应市场波动,以及快速采用新技术和实施更好的工作方式的灵活性。工业4.0提出了智能制造的原则,但在繁忙的生产环境中将理论变为现实可能具有挑战性。制造商需要切实可行的方法来利用和应用工业4.0的潜力,以提高运营效率,消除返工并提高利润率。这包括在任何时候计划、设计和持续改进单个流程的能力。

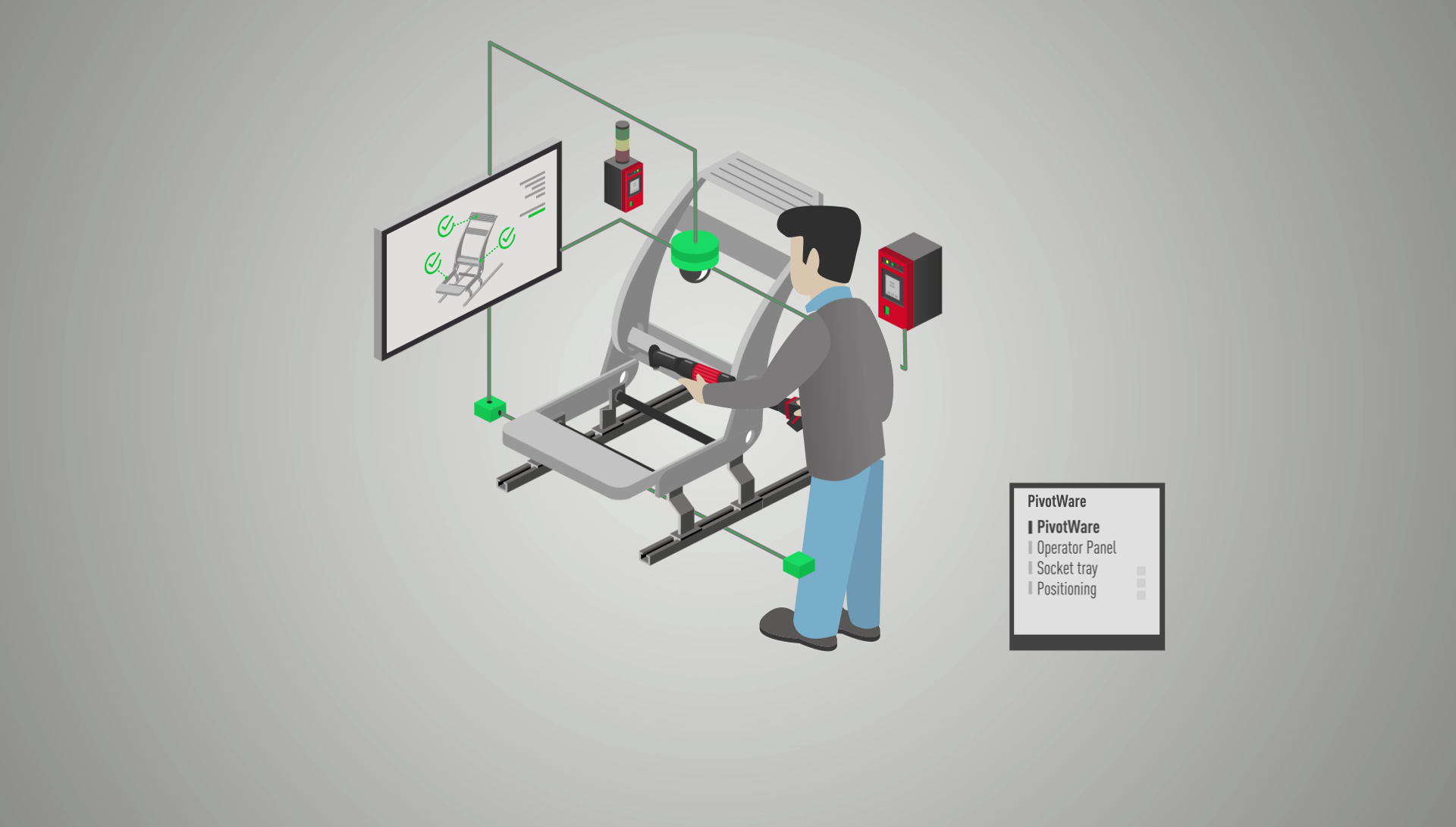

那么,如何应用连接、物联网(IoT)、数据挖掘和无缝集成来为您的业务带来巨大收益呢?关键是要逐步建立,直到你拥有一个智能生产生态系统,包括从智能装配工具到强大的数据分析的一切。

以下是马头动力关于开发可扩展、适应性强、面向未来的智能装配线的建议。